Gabion Basket Mesh: Specifications, Types, Uses, and Installation Guide

Aug. 15, 2025

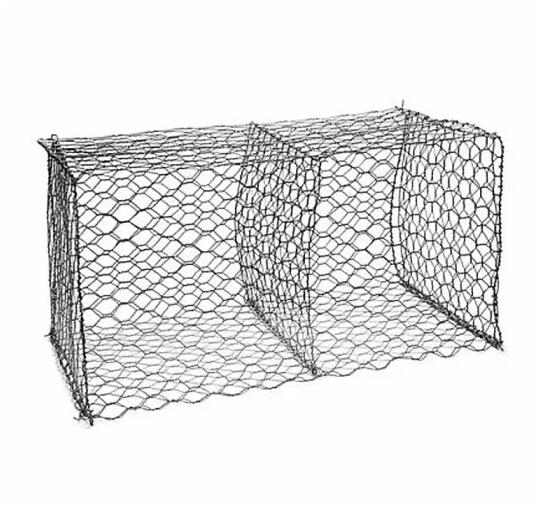

Gabion basket mesh is a critical component in civil engineering, landscaping, and erosion control projects. Designed to form durable, flexible structures when filled with rocks or stones, gabion mesh ensures long-lasting stability and functionality. This guide covers gabion basket mesh specifications, types, uses, installation, and the manufacturing process.

Gabion Basket Wire Mesh Specifications

The performance of gabion baskets largely depends on the wire mesh specifications. Key factors include:

Mesh Size: Commonly ranges from 50 × 50 mm, 75 × 75 mm, to 100 × 50 mm.

Wire Diameter: Typically between 2.7 mm and 5 mm depending on structural requirements.

Coating: Hot-dip galvanized, PVC-coated, or Galfan (zinc-aluminum alloy) for corrosion protection.

Weld Strength: Must meet industry standards (ASTM or EN) to withstand pressure and environmental stress.

Shape and Pattern: Rectangular or hexagonal meshes are available, each providing different levels of flexibility and strength.

Choosing the right specifications ensures the gabion basket remains durable and effective under varying conditions.

Types of Gabion Basket Mesh

Gabion basket mesh comes in different types to suit specific applications:

Welded Gabion Mesh – Rigid, strong, and ideal for heavy-load projects such as retaining walls.

Woven (Hexagonal) Gabion Mesh – Flexible, perfect for riverbanks, slopes, and areas with uneven terrain.

PVC-Coated Mesh – Enhanced corrosion resistance for wet or marine environments.

Stainless Steel Mesh – Long-lasting and aesthetically appealing, often used in decorative landscaping.

Selecting the proper type depends on project requirements, environmental conditions, and durability needs.

Uses of Gabion Basket Mesh

Gabion basket mesh is highly versatile and used in:

Retaining Walls – Stabilizing slopes and preventing soil erosion.

Riverbank Protection – Reducing erosion and managing water flow.

Bridge and Road Support – Reinforcing embankments and infrastructure foundations.

Landscaping – Building decorative walls, garden features, and seating areas.

Noise Barriers – Minimizing sound along highways and railways.

Its combination of strength, flexibility, and permeability makes it suitable for both functional and aesthetic projects.

Gabion Basket Mesh Installation Guide

Installing gabion basket mesh is straightforward if proper steps are followed:

Prepare the Site – Level and compact the ground; lay a solid foundation layer.

Assemble the Panels – Connect side, base, and lid panels using spiral binders, lacing wire, or C-rings.

Position the Gabion Basket – Ensure alignment and stability.

Add Internal Braces – Install stiffeners to maintain shape during filling.

Fill the Basket – Use hard, angular stones for stability and minimal shifting.

Secure the Top – Close and fasten the lid panel securely.

Proper installation ensures structural stability and long-lasting performance.

Gabion Basket Mesh Manufacturing Process

Gabion basket wire mesh is produced using a combination of wire drawing, cutting, and forming:

Wire Selection – High-quality steel wire is chosen for durability.

Galvanization or Coating – Wire is hot-dip galvanized or coated with PVC for corrosion resistance.

Mesh Formation – Wires are woven or welded into the desired mesh pattern (hexagonal or rectangular).

Panel Cutting and Assembly – Mesh panels are cut to size and prepared for shipment or on-site assembly.

Quality Control – Strength, coating thickness, and mesh integrity are tested before distribution.

This manufacturing process ensures that gabion baskets meet strict durability and performance standards.

133

0

0

Comments

All Comments (0)